FILTERATION ENGINEERS INDIA P. LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to FILTERATION ENGINEERS INDIA P. LTD.

Strainers

Various types of strainers are manufactured namely Y-Type, T-Type, Basket Type, Conical Type and Temporary Strainers. A filter element is housed inside a casing which filters solid particles from liquid or air. Filter elements are normally made up of wire mesh supported with a perforated sheet. Elements can be supplied for fine filtration up to 20 microns. Filter housing are available in fabricated, cast construction and different materials such as CI, CS, SS, Monel, Haste Alloy, PP, PVC, etc. Pressure rating from 150 lbs to 6000 lbs are available depending on the application.

Cyclone Seperators

Cyclone Separators are also known as Sand Separators or Centrifugal Separators. They require a minimum operating pressure of 2 kg/cm2. This filter does not contain any moving part or any filtration media hence there is zero maintenance and no choking of filter which leads to extremely low to zero pressure drop values

Duplex Basket Filters

Duplex Basket Filters are available with twin 3 way valve, sliding gate valve, butterfly valve, 6 way cam type valve, multi basket with common header designs with options of manual changeover of valve, automatic changeover of valve, manual backwash of filters and automatic backwash of filters. Each one of these filters are individually designed based on free flow area and pressure drop allowance values as required for the application also available in cast constructions. These can be supplied with wedge wire elements or perforated sheet and wire mesh as filtration media.

Coalescer

Coalescers are used for gas-liquid and liquid-liquid separation. Liquid condensates, lubricating oil, solid particles in any natural gas or process pipeline provide several maintenance problems with compressors and instrumentation. These units are capable of removing 99% solid and liquid particles of 1 micron size and above.

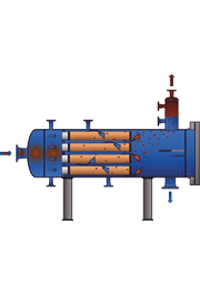

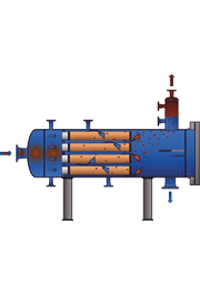

Debris Filters

Fouling phenomena are common and diverse, ranging from fouling of ship hulls, natural surfaces in the marine environment (marine fouling), fouling of heat-transfer components through ingredients contained in the cooling water or gases. Despite all of the pre-screening technology employed at raw cooling water intake sites, it is clear that additional filtration is often required to avoid macro fouling of the units served. The solution to this problem is provided by the Automatic Debris Filter. They can be supplied with wedge wire element or perforated sheet with wire mesh.

Pressure Sand Filters

Pressure sand filters are designed for higher flow rates per unit cross section area. These filters are designed with backwash arrangement which is done with the assistance of air blower and pump. We have supplied these filters for steel plants and power plants for filtration of raw intake water at suction side.

Simplex Basket Filters

Simplex Basket Filters are available in both Cast and Fabricated construction in inline and offset connections with flat bottoms or dish end as shell bottom. Each one of these filters are individually designed based on free flow area and pressure drop allowance values as required for the application. Various linings such as Rubber/PP/PVC/FRP/PTFE-FEP or any other epoxy can be done depending on applications, temperature and pressure. These can be supplied with wedge wire elements or perforated sheet and wire mesh as filtration media.

Self Cleaning Filters

Self Cleaning Filters are available in manual and automatic types. Our recommended filtration media for these type of filters is wedge wire element. Each of these filters are individually designed based on free flow area values depending on application, temperature and pressure.

Bag Filters And Air Filters

Bag filters have a simple quick opening system that allow change of filter bags to be completed such that vessel are out of use for minimum possible time. Bags can be extremely durable. Air filters are used for separating solid particles from air on suction side of fan, compressor machine, etc.

Suction Diffusers

Suction diffusers are installed at the suction side of a pump in either a horizontal or vertical position. It is designed to remove any foreign matter or impurities that may be hazardous to the pump or other system components, which may also affect their performance, while providing proper flow conditions to the pump. Suction diffuser has integral straightening vane to ensure uniform flow to the suction inlet of the pump and provides minimal pressure drop with its oversized body and screen. Suction Diffusers incorporate the functions of a strainer, flow straightener, elbow and pipe reducer in one compact unit thereby reducing installation costs.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.